Modular Construction And The Enabling Role Of BIM

July 16, 2020

The current pandemic may have led the construction companies into challenging timesdue to a disruption in the supply chain and shortage in manpower. But not all hope is lost.

Construction companies are turning to technology to help them get back on track, control costs, and work more efficiently. In that vein, they are increasingly adopting a promising way of construction called modular construction.

Once heralded as the next big thing in the construction industry along with 3-D printing, companies use modular construction to build certain pre-fabricated units offsite and then fit it with onsite structures. One can think of it as Lego blocks that are stacked one above the other to create a structure. Hopes from the technique are high. In fact, McKinsey predicts modular construction to be a $130 billion market by 2030.

Modular construction offers various benefits:

- It can accelerate the speed of construction by 50%

- It can lead to 20% cost savings

- It can reduce the labour costs of a project by 25%.

While modular construction has proven to be a boon for the construction industry, it has its challenges to pull off.

For instance, if the pre-fabricated unit is not precisely manufactured, it may not fit well with the onsite structure and could lead to cumbersome and disruptive rework. In fact, the company might have to incur 30% of additional costs due to rework.

That’s where technology like Building Information Modelling (BIM) can come to the rescue.

The Role Of BIM In Modular Construction

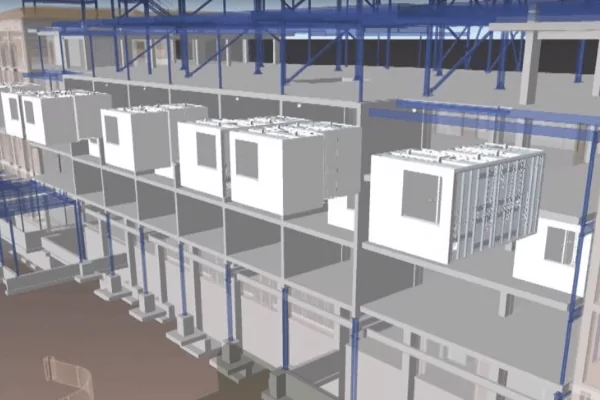

BIM promotes the creation of comprehensive, accurate, time-sensitive, and validated models of every little detail of the construction site. This level of detail can help construction companies to create a detailed 3D visualization of each component being constructed offsite as well that can fit perfectly within the rest of the structure that is documented just as clearly.

BIM can also help in:

1. Digitizing the construction workflow

Some construction companies have started thinking of concepts like Digital Engineering. A key component of this would be digitizing workflows. Automating these processes can drive up construction efficiency and reduce risk. Digitization can help companies to estimate costs accurately, reduce the reworks, promote transparency in project status, and maintain quality. Of course, given the wealth of information inherent to BIM, companies can create digitized workflows of the offsite construction of complex designs of components.

2. Enabling MEP coordination

Mechanical, Electrical, and Plumbing MEP coordination can be quite tedious and time-consuming. It accounts for almost 40% to 60% of the project. In the context of offsite modular construction, this is a crucial process because all three disciplines should be aware of the precise location of the proposed installation during the modeling phase. An oversight could lead to a major loss in time and effort. To ensure seamless integration among different plans, companies use BIM. BIM gives the specialists a 3D view of the structure in the pre-construction phase. It enables the specialists to identify potential clashes in the MEP systems and address them at an early stage itself. Modular construction benefits from the precision provided by BIM and minimize risks in pre-fabrication design.

3. Reducing cost escalation

As found by a study on the Korean construction industry, although modular construction is known to reduce costs, it could escalate costs if the initial planning is not done correctly or if the workforce is not skilled enough. BIM can help companies to address this issue by reducing escalating costs. It can help companies to streamline their construction workflows, reduce wastes in the pre-fabrication stage, and even find the right collaborators who can reduce insurance costs and tender risk premiums. According to a study by McKinsey, BIM has generated positive ROI for at least 75% of the construction companies.

4. Adhering to project schedule

Considering that both offsite and onsite development takes place simultaneously, modular construction can be completed 30% to 50% sooner than traditional constructions. It is particularly useful for construction companies as they can avoid risks or delays occurring due to extreme weather conditions that may prevail onsite. To coordinate efforts across locations and ensure seamless adherence to the project schedule, companies have been using BIM. Right from exchanging information to coordination, BIM enables the project managers to manage the project end-to-end effectively. It brings together all the stakeholders involved in the project, which ramps up the process of communication and eventually, the completion of the project. Countries like the UK and Norway also use BIM to submit their designs to the Governmentelectronically, so they can quickly check if the construction complies with the regulations and approve it.

5. Reducing wastage of pre-fabricated material

The iconic 50-storeyed Leadenhall Building in London may be a landmark for tourists. However, architects know it for its sustainable model of construction. The Leadenhall Building is a fine example of how modular construction can help companies to achieve zero waste as most of the components are designed and manufactured offsite. Apart from cutting labour costs and improving productivity, modular constructions are also known to help build sustainable buildings. It can reduce up to 90% of waste. And of course, with BIM project managers can reduce wastage effectively. Considering that the drawings are made in 3D, it allows the stakeholders to visualize the plan, identify errors, and rectify them early. It reduces the chances of rework and brings in precision in the entire process.

Conclusion

It is clear that the techniques of modular construction along with the power of BIM can help construction companies to boost the progress and quality of their projects. No wonder world over governments and construction companies are backing BIM to fast-track projects. Have you considered how BIM can help you drive up your effective implementation of offsite modular construction?