The world eagerly awaits the Paris Olympics 2024, starting from 26th July 2024. At the Paris Olympics, we witness the extraordinary performances of athletes and the latest innovations in modern technology.

The Paris Olympics are a game-changer, as it is the first in history to be completely digitalized for a futuristic games experience. Digital Twins technology is used at the Olympic venues, the same technology will also be used for the Paris Paralympic 2024.

Before we move ahead let’s understand what exactly Digital Twins technology is.

What is Digital Twins technology?

What if I say, to host the Paris Olympics 2024, the organizing committee and stakeholders designed the two same models of the Olympic Village, I know this sounds funny, but this is true and this is what Digital Twins can do.

In simple language Digital Twins means the virtual and the exact model of the physical entity, it may be a building, machine, stadium, or an entire city.

Let’s make it simpler from the above example.

There are two identical Olympic villages, one is the real place where the actual games are happening, and the other is a virtual version. Sensors fitted in the real village to collect data on things like weather, lights, and sound. This data is sent to the virtual village, where we can see everything and make changes in real-time. This way, we can keep everything running smoothly during the games.

The core purpose of the Digital Twins is to make the system more efficient and sustainable.

History of Digital Twins

The thought of Digital Twins was first introduced in the year 1960 by NASA for the Apollo mission, however, the name Digital Twin was not given at that time. The idea was to test and evaluate the possible solutions from Earth.

Dr. Michael Grieve from the University of Michigan was the first who use Digital Twins when he was working on the project Product Lifecycle Management (PLM). Later, other industries also started implementing Digital Twins technology.

How Digital Twins Enhance the Olympics?

Digital Twins offers a realistic view to the Olympic Games organizing committee and the stakeholders so that they can plan and visualize all the aspects including transport, crowd management, security, etc., and fix them in real-time.

The organizing committee partnered with the UK-based company One Plan. One Plans GIS (Geographic Information Software) mapping tool creates digital venues that show the entire space from any angle and in any weather situation. This will help to see the lighting, audio, cameras, televisions, etc. and, according to this, can make the possible changes without visiting the site.

Some additional important uses of digital twin technology in the Paris Olympics 2024.

Decision-making support planning

Digital twins provide real-time data and analytics, which help event organizers with processes such as security planning, ticket pricing, and more.

Post Event Analysis

Digital twins store all the data collected during ongoing events, which can be reviewed post-event. This helps organizers calculate the success of the event and identify key areas for improvement.

Interoperability:

The 3D digital twins are completely interoperable with the 2D maps in the system, when any change happens immediately it will show in 3D. This gives organizers complete access to real- time plans for every venue so they can plan collaboratively.

Paris 2024 will be a landmark Olympic and Paralympic Games, driven by innovation and sustainability,” – Paul Foster (Chief Executive and Founder of OnePlan).

Digital Twins in Swim Training

The US Swim team will also use the Digital Twins at the 2024 Olympics games to enhance their performances.

Ken Ono mathematics professor from the University of Virginia and his team created the digital twins of swimmers and worked with US swimming team members. In a study, they found that the movement of the replicate model of the original swimmer offers valuable insights.

They said digital twins help to find what factors affect the swimmer’s performance like power, muscle strength, and range of motion, this will help to make changes in the swimmers and enhance their performance.

Scientists made a suite of sensors for US swimmers they called it an Inertial Measurement Unit. This suit captures the high-resolution data with 512 frames of information a second, this is 20 times higher than the conventional methods.

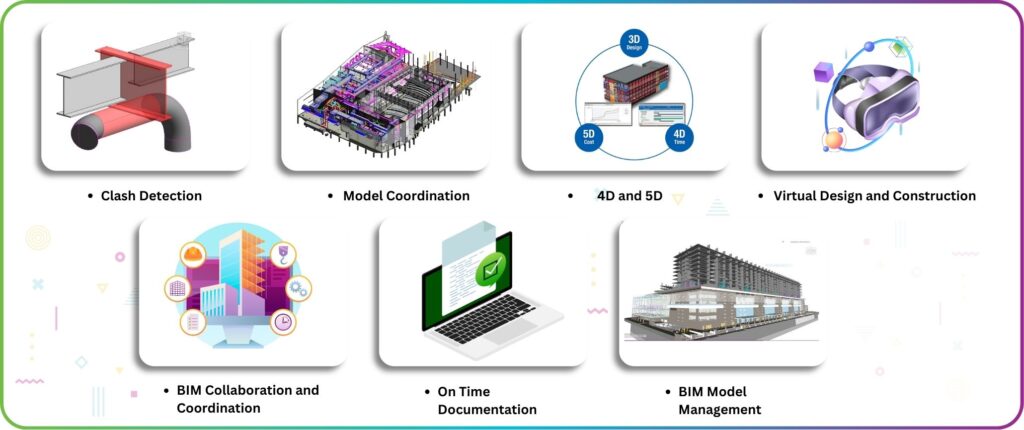

Let’s understand the industries and the market size of Digital Twins

Industries actively use Digital Twins technology

In the upcoming years, more industries are set to integrate Digital Twins technology to transform their operations and achieve greater efficiencies.

Market size of Digital Twins

In 2022, the market size of Digital Twins was $6.9 billion, in 2023 it was $10.1 billion. According to research firm Markets And Markets, the Digital Twins market is expected to grow at a CAGR of 61.3%, increasing from $6.9 billion to $110.1 billion by the end of 2028.

We already discussed that the Digital Twins have made a significant impact across various industries such as transportation, construction, and healthcare, but their application in the Olympic Games is particularly noteworthy.

This innovative use of Digital Twins technology offers a unique opportunity to explore how it can enhance the management and experience of one of the world’s most prestigious sporting events. This will open doors for other sports to utilize digital twins.